Project Leader: Prof. Dr. Hab. Wojciech Kujawski

Project Description

Renewable biofuels should replace fossil fuels to partially mitigate climate change. Currently, oxygen-containing biofuels (such as butanol or ethanol) are blended with gasoline (up to 10%). Research on biohydrogen is still at an early stage.

The Mem4bioFuels project (“Membranes for Renewable Fuels”) is designed as an interdisciplinary initiative, encompassing the following stages:

- Development of improved membranes with enhanced separation properties when in contact with diluted organic solvents (hydrophobic membranes for pervaporation and thermal pervaporation) and resistance to adverse effects such as fouling and polarization (hydrophilic membranes for microfiltration).

- Evaluation of the efficiency of the developed membranes in separating streams generated in biorefineries, both under laboratory and industrial conditions.

- Description of an integrated process, including material recycling and economic feasibility analysis (market analysis).

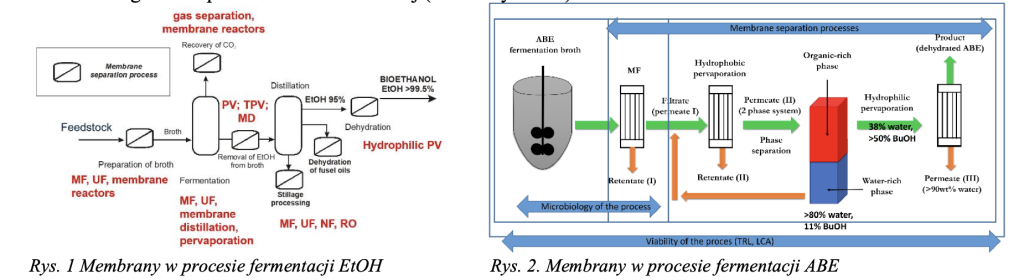

Membrane separation techniques can improve fermentation processes for biofuels by continuously removing fermentation products. Examples of membrane techniques potentially applicable to bioethanol fermentation are shown in Fig. 1, while Fig. 2 illustrates the biobutanol production scheme. An important process is microfiltration, which clarifies the mash by retaining all particles larger than the membrane pores. However, membranes are prone to bio-fouling, necessitating the development of new membranes with reduced susceptibility to contamination. The team has experience in modifying membranes to obtain surfaces with limited fouling tendencies (implementation of Stage 1).

The next stage involves recovering solvents from the mash. In typical fermentation processes, the content of volatile components is low; however, using pervaporation, thermal pervaporation, or membrane distillation, the concentration of these solvents can be increased to levels that make subsequent distillation economically feasible. The project plans to develop modified mixed-matrix membranes (MMM) with enhanced separation and transport properties (Stage 1).

Stage 2 will be carried out using both synthetic mixtures and mixtures derived from actual bioreactors. The outcome of this stage should be the determination of optimal process parameters to obtain dehydrated organic solvents (ethanol – Fig. 1, or an ethanol/butanol/acetone mixture – Fig. 2). Collaboration with fermentation/biofermentation groups and the use of chemometric methods is planned for this stage.

Ethanol fermentation primarily produces ethanol (EtOH), but higher alcohols (so-called fusel oils) are also generated and typically recovered by distillation. These by-products are valuable, and membrane techniques are also used, especially for their preliminary dehydration.

For the recovery of products from ABE fermentation, after concentration via hydrophobic pervaporation, the organic content reaches around 60 wt.%. Due to the limited solubility of butanol in water, phase separation occurs naturally. The water-rich phase can be returned to hydrophobic pervaporation, while the organic-rich phase is sent for final dehydration via hydrophilic pervaporation. The result is a dehydrated acetone–butanol–ethanol mixture, which can be used directly or further fractionated by distillation.

A similar approach can be applied to biohydrogen obtained via fermentation. Stage 3 will be implemented in close collaboration with teams from the Faculty of Economics and Management, UMK.

The core research team consists of members of the Membrane and Membrane Techniques Group (Faculty of Chemistry, UMK), who have extensive experience in research projects, including international collaborations. Team members (e.g., Dr. Katarzyna Knozowska) have expertise in membrane modification and characterization using various nanomaterials. Prof. Aleksandra Szydłowska-Czerniak and Dr. Hab. Piotr Szczepański, Prof. UMK, are well known for their experience with chemometric methods.

Collaboration is planned with the Department of Analytical and Applied Spectroscopy Chemistry and the Department of Chemical Technology at the Faculty of Chemistry. The fermented mash used for studies on membrane surface fouling will be sourced through collaboration with groups from the Faculty of Biological and Veterinary Sciences or the Interdisciplinary Center for Modern Technologies.